INNOVATORS IN TESTING TECHNOLOGY

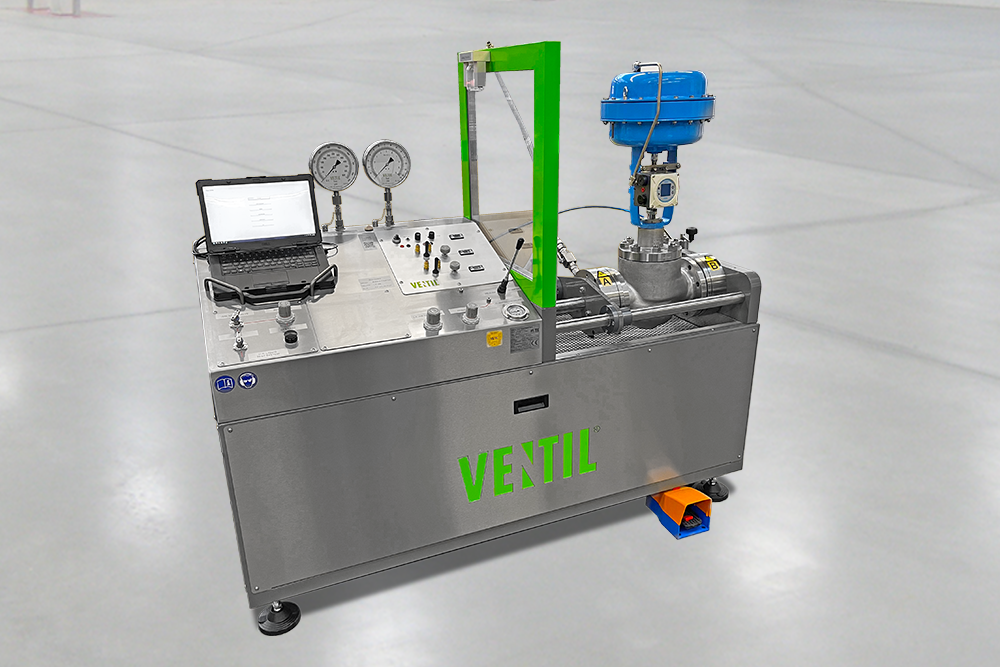

"We have built a worldwide reputation for design, custom engineering, manufacturing and maintain VALVE TEST- & REPAIR EQUIPMENT, which endures."

As a leading manufacturer of valve test equipment, we are dedicated to enhancing the safety, reliability and integrity of industrial installations worldwide.

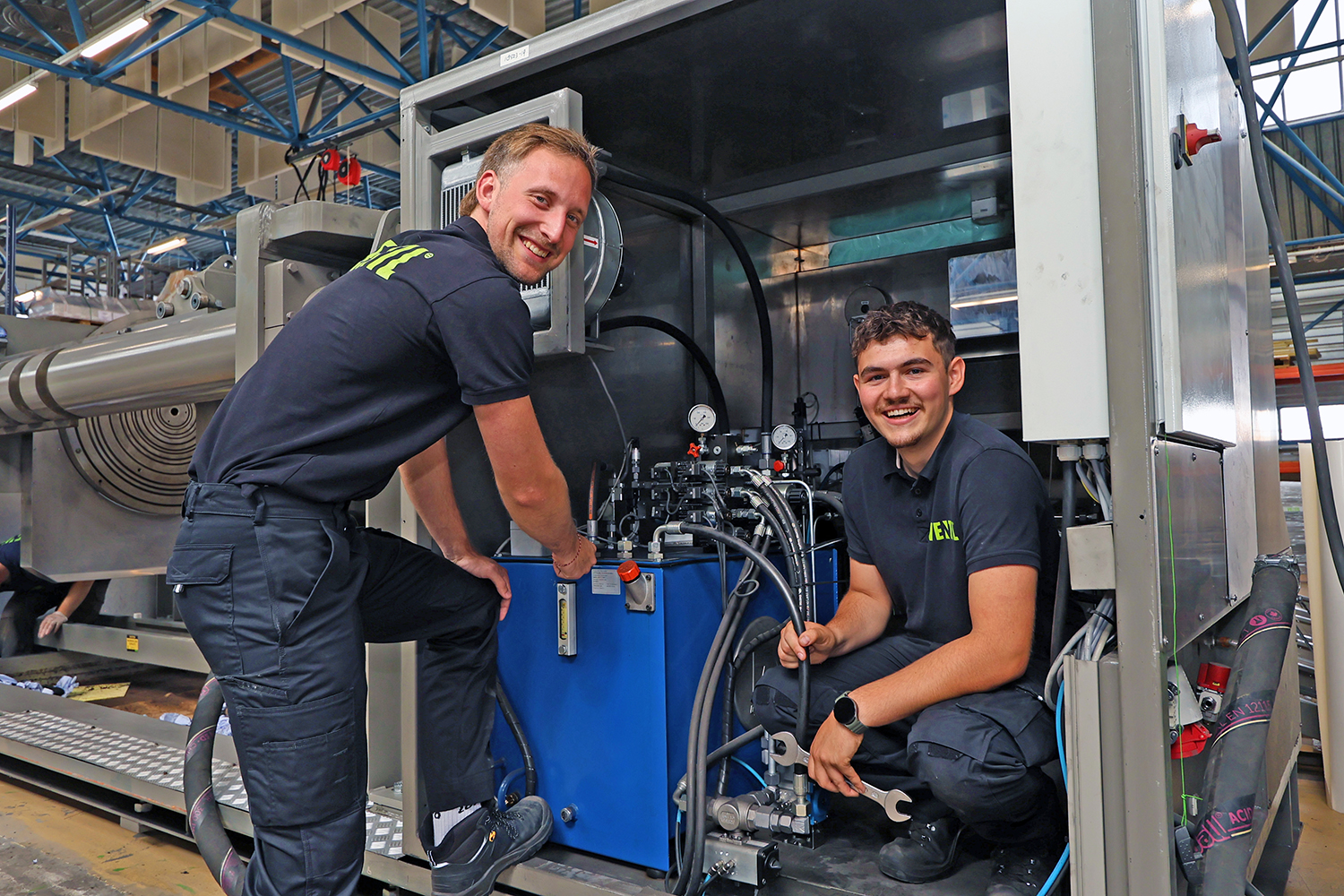

Founded in 1954 as a family-owned business in the valve industry, we have evolved into a global specialist in pressure testing solutions for valves. From our facilities in the Netherlands, United Kingdom, United States and United Arab Emirates, we support end users, valve manufacturers, service providers and inspection bodies across the globe.

We are committed to improve safety, environmental and operating performance of industrial facilities.

Get inspired by VENTIL’s technologies, expertise and latest insights.

How can we support your operation?

INDUSTRIAL INNOVATION

Re-certification of pressure relief- and safety valves is mandatory. To support this process, in-situ testing can add significant value to risk-based assessments and complement traditional bench testing. With an Auxiliary Lift Assist Device (ALAD), testing spring-operated Pressure Relief Valves (PRVs) becomes simpler, smarter, and more efficient. The key advantage: PRVs can be functionally tested in situ, as long as the procedure is carried out correctly and with the appropriate equipment. For optimal results, the PREVENTEST NEXUS is considered the best choice for performing ALAD tests, ensuring precision, safety and compliance with industry standards.